“Why Post Protector?” video with wood scientist, Dr. Shane Kitchens.

In this short video, Dr Kitchens explains the, often misunderstood, simple science behind decay and decay prevention.

POST DECAY 101: A Wood Scientist Explains

In-Ground Post Decay: Mr. Misunderstood

In-ground post decay is almost always misunderstood as most believe decay is caused by moisture. Moisture is not the cause of decay, rather one of the conditions needed for decay to occur.

In-ground post decay is almost always misunderstood as most believe decay is caused by moisture. Moisture is not the cause of decay, rather one of the conditions needed for decay to occur.

The three conditions needed for decay:

1. Moisture saturation of wood fiber

2. Oxygen

3. Temperature between 40-100 degrees

These conditions enable soil fungi to feed on the wood fiber! AKA, DECAY!

With that said, the chemical preservative used to pressure-treat posts is a pesticide designed specifically to envenom the wood fiber so it becomes an unsuitable food source for the soil fungi.

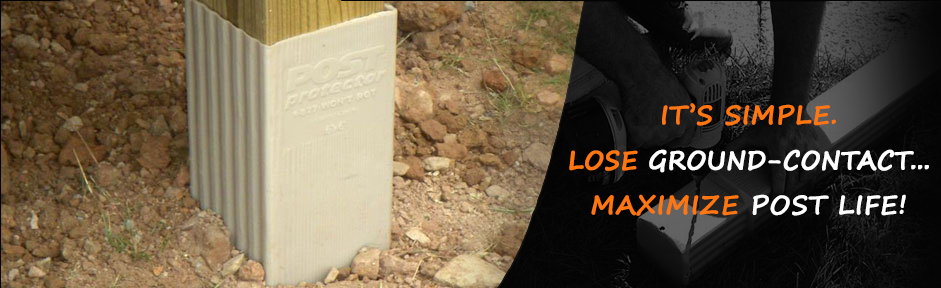

Post Protector’s “barrier” protection works with the treatment to fight decay by eliminating soil-to-post contact, therefore, preventing access of soil fungi to the post.

Here’s what a wood preservative manufacturer has to say:

“Barrier” protection will substantially increase the lifespan of any pole by protecting it from fungal & insect attack far more effectively than a preservative treatment alone can achieve while preventing preservatives from leaching into the environment.”

Barrier Protection for In-Ground Posts

What do Wood Preservative Manufacturers Think?

First, Post Protector provides, simple, slide-on, “Barrier” protection for in-ground posts with 2 main objectives.

1. Decay Protection by eliminating soil-to-post contact and the ability of the soil fungi to access and feed on the post. AKA, DECAY!

2. Environmental Protection by confining chemical preservatives to the post.

Wood preservative manufacturers produce the chemicals used to “pressure-treat” ground-contact posts.

The preservative is used to envenom the wood fiber so it becomes an undesirable food source for the soil fungi.

Some of these preservative producers also have utility pole divisions.

They manufacture, install, and maintain pressure-treated utility poles for North American utilities.

They, too, advocate “barrier” protection to work in conjunction with their pressure treated utility poles as part of a logical two-pronged approach.

Here’s what 2 preservative manufacturers, the foremost experts in wood preservation, have to say about adding “barrier” protection:

“Barrier protection will substantially increase the lifespan of any utility pole by protecting it from fungal & insect attack far more effectively than a preservative treatment alone can achieve while preventing preservatives from leaching into the environment.”

“Barrier systems prevent the invasion of wood-destroying fungi and termites which typically occurs as the preservative migrates from the wood leaving it vulnerable to attack.”

Post Protector’s “barrier” protection offers a simple, sensible, & eco-friendly approach to post foundation projects like pole barns, decks, fences, & pergolas, to name a few.

Post Protector addresses the longevity and environmental concerns often associated with typical in-ground-post foundations.

Post Protector + pressure treated post foundations are faster, more affordable, often stronger, and more DIY friendly vs. “pier & bracket” or any other methods designed specifically to eliminate soil-to-post contact.

Barrier Protection for In-Ground Posts

What do Wood Scientists Think?

The concept of barrier protection for in-ground posts is nothing new to the scientific community. Wood Scientists have conducted numerous studies over the past 20 years to test barrier protection effectiveness. Here’s a sampling of what wood scientists found.

#1 Oregon State University (1997)

Barrier boots were placed on both treated and untreated wood in-soil contact.

NO attempt was made to keep water from entering the upper open end of the boots.

The barrier boots effectively prevented any fungal attack, even on the untreated stakes, by acting as an additional layer of protection against soil dwelling fungi.

In comparison, the unbooted stakes showed evidence of attack.

#2 Dr. Albin Baecker (1998)

Pole failure can be prevented if soil fungi are excluded from pole contact.

Field trials proved that barrier systems prevented access of decay fungi to poles.

Preservatives are designed to prevent decay of in-service poles, but treated poles may fail prematurely through insect and fungal attack.

The “barrier system” is a biotechnological device that prevents insect and fungal attack, while simultaneously acting as an environmental barrier, which confines the preservative to the pole.

#3 Termite Tests at Mississippi University (2000)

Termite resistance tests were conducted at Mississippi State University on barrier wrapped wood in comparison to non-wrapped wood.

In this severe test, the barrier wrap clearly showed its termite resistance capabilities.

There was no attack on any of the wrapped stakes while the unwrapped stakes had mostly heavy attack and some with moderate attack.

#4 Dr. Alan Graham, Dr. Laurie Cookson, Dr. Andrew Percy (2003)

A field liner or barrier was used to encase the base of posts to retain preservative while preventing soil-to-post contact.

No decay was found with the lightly preserved posts with the barrier.

These barriers were thus shown to confer considerable protection on wooden posts (with or without preservative) from decay fungi in soil.

#5 Dr. Barnes & Colleagues Study (2013)

The longevity of treated wood embedded in soil is increased when a barrier system is used.

Electric Power Research Institute (EPRI)

In a Study initiated in 2003, and is ongoing, demonstrates that preservative movement out of treated poles equipped with barrier wraps is blocked. Impermeable barrier wraps impedes leaching into the surrounding environment.

Forinek-Canada (Western Lab), PowerTech Labs, BC Science Council, & BC Hydro

Soil Bed tests were performed by Forinek-Canada (Western Lab), PowerTech Labs, the BC Science Council, and BC Hydro on CCA-C treated and untreated Lodgepole pine posts. In high decay conditions for over eight years found that the performance increase due to booting (barrier wrapping) was 2.5 times greater on a retention basis.

What Causes Wood Rot?

http://www.deckmagazine.com/design-construction/what-causes-wood-to-rot_o

by Colin McCown, executive vice president of the American Wood Protection Association (AWPA)

“Post Protector’s “barrier” protection eliminates soil-to-post contact, therefore, the decay causing soil-fungi cannot access the post to use the wood fiber as their food source.”